Quality Control in Pharmaceuticals: What You Need to Know About Safe Medications

When you pick up a prescription or buy a generic pill at the store, you trust that it will work the way it should. That trust isn’t accidental—it’s built on quality control, the systematic process of ensuring medications meet strict standards for strength, purity, and consistency. Also known as pharmaceutical quality assurance, it’s the invisible guardrail between a medicine that heals and one that harms. Without it, a batch of antibiotics could be too weak to fight infection, a painkiller might contain toxic fillers, or a heart medication could break down before it even reaches your bloodstream.

FDA regulations, the legal framework that governs how drugs are made and tested in the U.S. are the backbone of this system. Every generic drug approved by the FDA must prove it’s bioequivalent to the brand-name version—not just in ingredients, but in how your body absorbs it. This isn’t a formality; it’s a science. Stability testing, batch sampling, and cleanroom manufacturing are all part of the process. And when something goes wrong—like a contaminated batch or a mislabeled vial—the FDA steps in with recalls. That’s why you see alerts about tainted blood pressure meds or expired insulin. These aren’t rare events; they’re why drug safety, the ongoing monitoring of medications after they hit the market exists. It’s not enough to make a safe drug—you have to keep checking it.

For compounded medications—custom formulas made for specific patients—quality control gets even more critical. Unlike mass-produced pills, these aren’t tested in huge batches. That means the pharmacy making them must follow strict guidelines, like CGMP, Current Good Manufacturing Practices, the gold standard for pharmaceutical production. If they don’t, you could be getting a compound that’s too strong, too weak, or contaminated with mold. That’s not theoretical. There have been real cases where patients got sick from poorly made compounded drugs. That’s why knowing where your compound comes from matters as much as what’s in it.

What you’ll find in the posts below isn’t just a list of articles—it’s a look at how quality control shows up in real life. From how the FDA inspects generic drug factories to why finishing your antibiotic course ties into preventing drug-resistant infections, these stories show the chain of responsibility that keeps you safe. You’ll see how stability testing affects approval timelines, how recalls happen, and why even small mistakes in labeling can have big consequences. This isn’t about bureaucracy. It’s about the difference between a pill that works and one that doesn’t—and how much you deserve to know what’s in it.

- 11 Comments

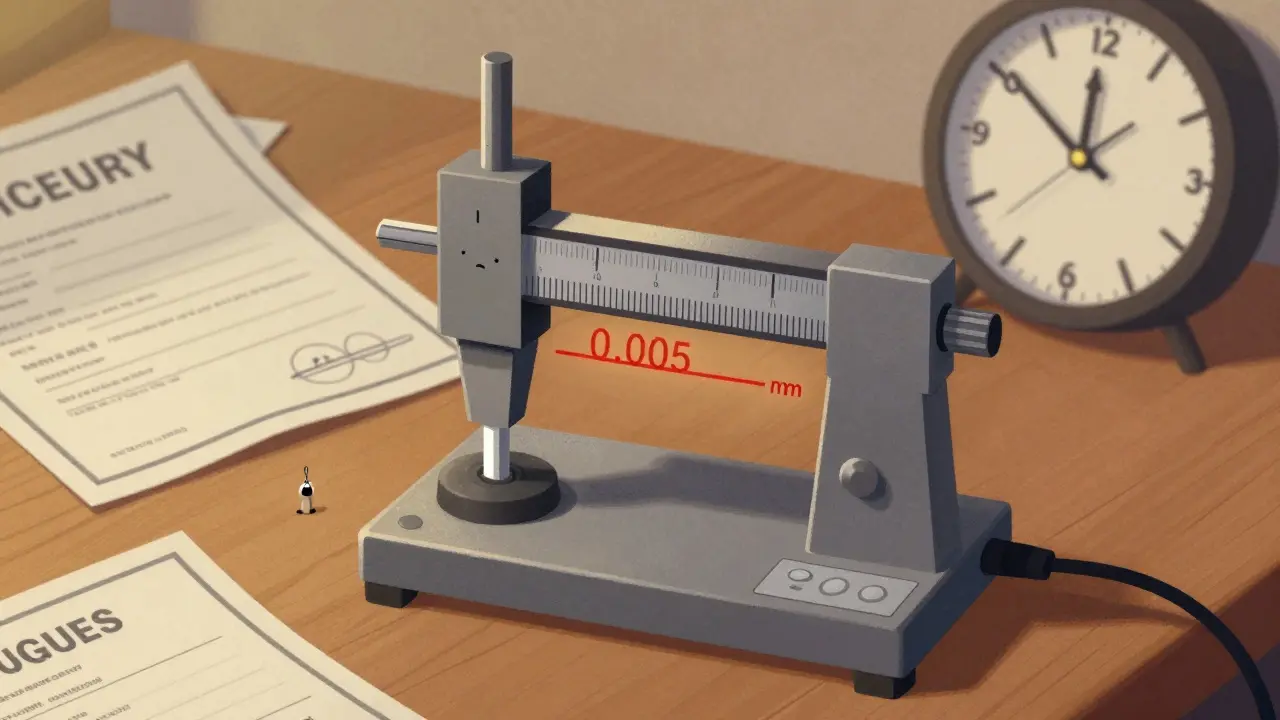

Calibration and validation are essential for manufacturing quality, especially in medical devices. Learn how to meet ISO 13485, FDA, and CLIA requirements, set proper intervals, avoid common mistakes, and prepare for 2026 electronic record mandates.

- 10 Comments

Corrective actions in manufacturing go beyond fixing defects-they eliminate root causes to prevent recurrence. Learn how structured CAPA systems, rooted in FDA and ISO standards, reduce defects, cut costs, and ensure compliance.