Bioequivalence: What It Means for Generic Drugs and Your Health

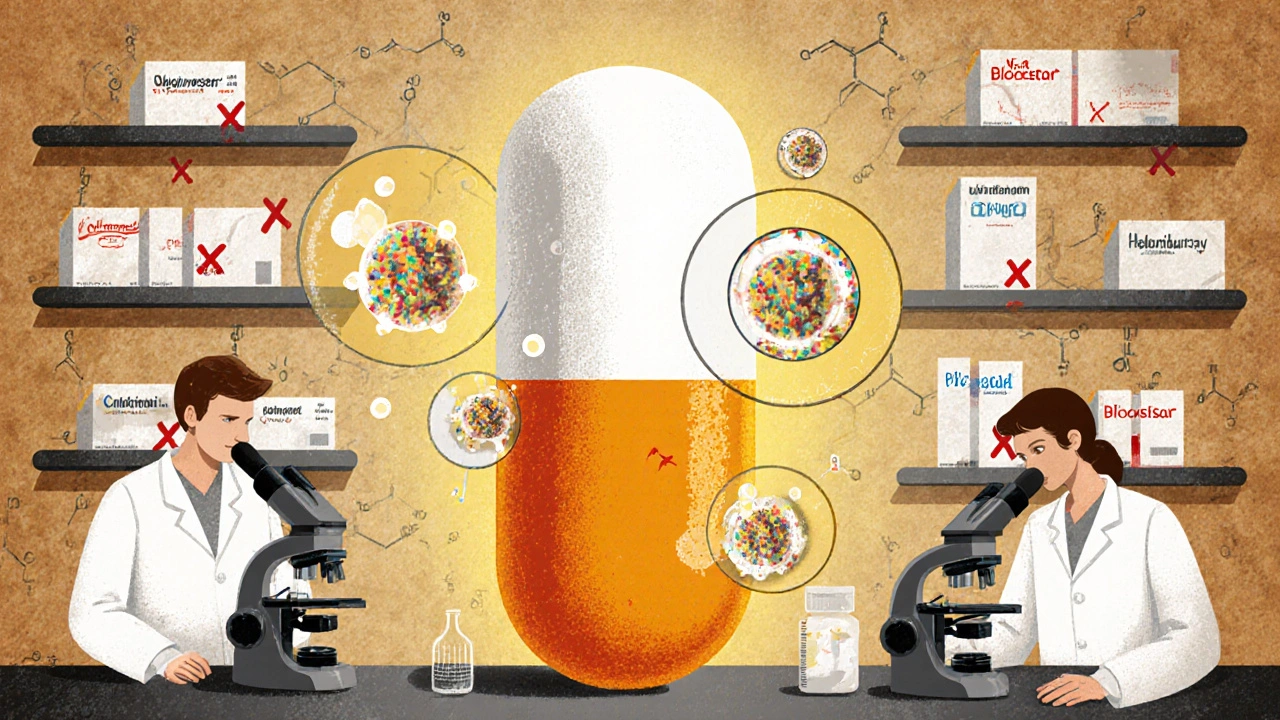

When you pick up a generic pill, you’re trusting that it will do the same job as the brand-name version. That trust comes from bioequivalence, a scientific standard proving two drug products deliver the same amount of active ingredient at the same rate in the body. Also known as therapeutic equivalence, it’s the reason your pharmacist can swap a brand-name statin for a generic without your doctor having to reauthorize it. Without bioequivalence, generics could be weaker, slower to work, or even unsafe—and that’s not just theory. The FDA requires it for every single generic approved in the U.S.

There are two main ways to prove bioequivalence: in vivo bioequivalence, testing in real people using blood samples to measure how fast and how much of the drug enters the bloodstream, and in vitro bioequivalence, lab tests that check how the drug dissolves under controlled conditions. For complex drugs like those with special coatings or slow-release formulas, the FDA still leans on human trials. But for simpler pills, they’re increasingly using dissolution tests alone—faster, cheaper, and just as reliable if done right. This shift is changing how generics are approved, and it’s why some newer generics hit shelves faster than ever.

But bioequivalence isn’t just about science. It’s about access. It’s why a 30-day supply of a generic blood pressure pill costs $4 instead of $300. It’s why seniors on fixed incomes can keep taking their meds. And it’s why your doctor can confidently switch you to a generic after your brand-name patent expires. The posts below dig into exactly how this works behind the scenes: how the FDA tests generics, what happens when a batch fails, why some generics get rejected, and how companies prove their products match the original. You’ll also find real examples of how bioequivalence impacts everyday medications—from statins to migraine combos to heart rhythm drugs—all of which rely on this invisible standard to be safe, affordable, and effective.

- 0 Comments

Generic drugs work just like brand-name medications but cost up to 85% less. Learn how they're regulated, when to stick with brand-name, and what to watch for if you're on thyroid, seizure, or blood thinner meds.

- 11 Comments

Generic drugs save billions in healthcare costs and make up 90% of U.S. prescriptions. Learn how they're made, from reverse-engineering brand-name pills to FDA-approved manufacturing under strict quality controls.